It's a low cost and easy way of creating a store of your own yeasts with possible storage times of up to 2 years if kept in the fridge, and unlike many instructional videos and posts, only 1 bottle of commercial beer is required. You can also use the same method for recovering yeast from your own Home-brew beers that you have made in the past.

The way I store my yeasts is in 50ml centrifuge vials with 80% Isotonic sodium chloride with each vial containing enough yeast for up-to five 23 litre batches of beer. That's 10ml of yeast with 40ml of NaCl 0.9%.

I decided on this method of storage mainly because is was simple and had a long enough storage life for what I needed.

I decided on this method of storage mainly because is was simple and had a long enough storage life for what I needed.

This post I'll split up into sections : Initial Recovery, Yeast Step Up, Storage Procedure as each stage can be used independently from each other.

For Example : You could recover the yeast from a bottle of beer, step it up to a 1 litre Starter and pitch into a new beer,

Or:

Use the yeast cake from a fermented beer you have just done, wash then store that yeast for a future brew-day.

Initial Recovery

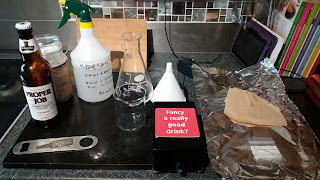

Equipment

- A bottle of bottle conditioned Beer (Proper Job St Austell Brewery)

- 10g of Dry Malt Extract

- StarSan

- Pyrex 250 ml Kitchen Lab Measure and Mix Beaker

- 500ml Glass Conical Flask

- Funnel

- Coffee Filter

- Tin Foil

- Stir-plate and Stir-bar

Note: Have your bottle of beer at room temperature and leave it to settle out any yeast for a few days to maximise the yeast sediment in the bottle.

Method

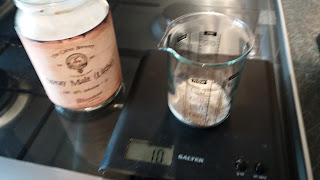

The first thing we need to do is make up some low gravity medium for the yeast to grow in, for this weigh out 10g of Light DME into your 250ml Beaker and then add 150ml of water. Mix it well and then put it onto boil, we have added more water than most internet instructions because my method we will be boiling the low SG wort twice so the added water allows for the increased boil off.

The first thing we need to do is make up some low gravity medium for the yeast to grow in, for this weigh out 10g of Light DME into your 250ml Beaker and then add 150ml of water. Mix it well and then put it onto boil, we have added more water than most internet instructions because my method we will be boiling the low SG wort twice so the added water allows for the increased boil off. Once up to the boil set a timer for 15 mins, but keep a good eye out for boil overs as they make a right old sticky mess.

When the 15 min boil is complete, cool the wort, I just use my sink filled with cold water. Get the wort to a temperature of about 20'c

You can now pour the wort through the funnel and coffee filter paper into the 500ml Glass Conical Flask. This is just to removed as much of the hot and cold break proteins from the Wort as possible.

I started doing this filter stage after seeing a video on making Agar plates and it made for a cleaner yeast collection later on as most of the Trub is removed by doing this extra step.

As you can see we have a crystal clear Wort in the flask.

Put this back on the heat and boil for 10 more minutes to resterilise the Wort and it's new container.

Once this boil is complete, we should have around 100ml of Wort left. It really doesn't matter if there happens to be a little less or a little more Wort, it will still be only around 1.030 SG give or take.

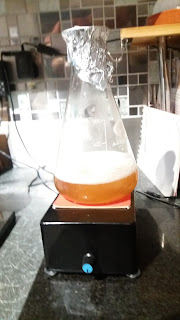

Drop your Starsan'ed Stir-Bar into the hot Wort, watch out for it foaming up when you do this, and cover the flasks opening with a piece of Starsan'ed tin foil.

Cool the Wort again to 20'c, and this time also make sure the sides and neck of the flask are cool to the touch as we don't want to kill of any yeast due to hot glassware.

Starsan the Beer Bottle around the crown cap and your bottle opener to kill off any nasties that might be on them and carefully pour your beer into a glass leaving the last 10-15mm or so of beer and yeast in the bottom. Place the crown cap back on the bottle.

Give what is left in the bottle a swirl up to dislodge the yeast sediment, Starsan the bottle neck again, remove the crown cap and pour this into your cooled Wort.

Place on your Stir-plate at 20'c for 4 days so that the yeast can multiply.

Yeast Step Up

Equipment

- 90g of Dry Malt Extract

- StarSan

- 2000ml Glass Conical Flask

- Funnel

- Coffee Filter

- Tin Foil

- Stir-plate and Stir-bar

Method

Just the same as before but with larger quantities of water (1000ml) and DME (90g) make up a fresh batch of Wort.Pass through the coffee filter and then reboil the cleaned wort for another 10 mins. This will reduce the volume to around the 900ml mark.

Cover again with foil and cool to pitching temperature

Add the 100ml starter to the new 900ml starter we have just made and place back onto the stir-plate for another 4 days so the yeast can multiply sufficiently enough that we can collect the required volume for storage.

Yeast Recovery & Storage

Equipment

When I decided to start banking yeast with this method I made up 25 vials filled to 40ml in one hit. The vials where sterile when I received them and the 1000ml bottle of NaCl 0.9% was of the type where you can not reseal the bottle once opened.

40ml x 25 bottles = 1000ml which worked out very well.

Method

Now that the quantity of yeast has grown to a sizeable amount while on the stir-plate, we can now go ahead and collect the yeast for storage.

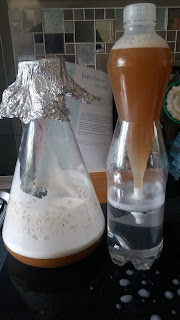

My method at the moment is to decant some of the yeast and Wort from the 1000ml starter that we stepped up the yeast into my 250ml separatory funnel and leave it to settle out

any yeast for a few days in the fridge to maximise the yeast sediment. I have found that 250ml of yeastie Wort produces just over 10ml of thick yeast which is what we need in the NaCl 0.9% prepared vial.

My method at the moment is to decant some of the yeast and Wort from the 1000ml starter that we stepped up the yeast into my 250ml separatory funnel and leave it to settle out

any yeast for a few days in the fridge to maximise the yeast sediment. I have found that 250ml of yeastie Wort produces just over 10ml of thick yeast which is what we need in the NaCl 0.9% prepared vial. It's a good idea to have 2 or 3 vials of NaCl also in the fridge so they are at the same temperature as the yeast so when we add the yeast to the vials they don't get thermal shocked.

I may look more into this final step to give cleaner results, but currently this is working great for me, even tho' I do get a very small amount of Wort in the final storage vial.

The liquid in the bottom of DIY separatory funnel stand, a cut down soda bottle, is just Starsan, mainly to keep the outlet of the funnel clean and to also give it some weight so it doesn't get knocked over so easily in the door of my fridge

Once the yeast has settled to the bottom of the 250ml separatory funnel, clean a vial of NaCl with some Starsan and near a flame, I just use the gas stove top, with the small burner on, decant the thick yeast into the vial until it reaches the 50ml mark. Cap the vial, label and store for future use in the fridge.

Using The Stored Yeast

Let the starter grow for up to seven days. You will notice a growing thin layer of yeast on the bottom of your vessel. From there you will want to increase the starter size to 1 litre. Add 900 mls of freshly prepared wort on top of the existing 100 mls. In 2 or 3 days you should have roughly the same amount of cells in a fresh vial you would have picked up from your local homebrew shop.

No comments:

Post a Comment